Alongside the end goal of green sand molding services, Seneca Foundry offers a variety of 3D Scanning services. The Romer Arm, 3D Scanning Reports, Color Mapping, and Reverse Engineering capabilities used are all made possible with our total quality management system to make us your trusted cast iron manufacturer.

7 Axis Romer Absolute Arm

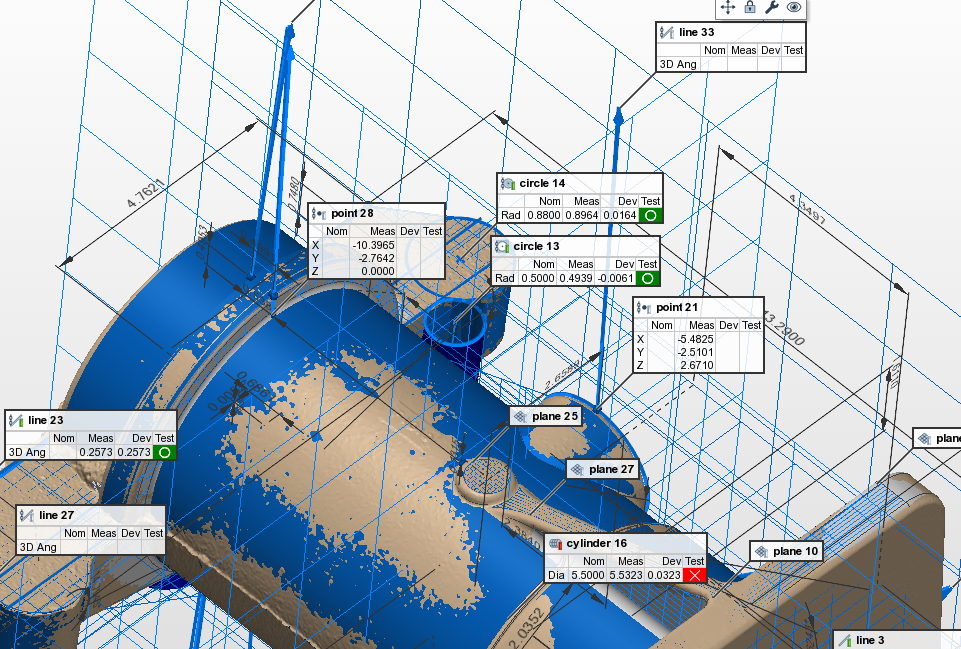

To allow for quality gray and cast iron castings, we use the 7 Axis Romer Absolute Arm, a versatile metrology tool, that is a replacement for traditional measurement devices. The probing accuracy is certified according to ISO 10360-12, with full scanning system accuracy certified according to ISO 10360-8.

At Seneca Foundry we dignify ourselves on our consistent quality with our casting services ranging from gray iron, to ductile iron, to green sand molding, to everything in between. To achieve this, we are continuously evolving with technology to stay at the forefront of our industry.

The acquisition of the Romer Arm has helped us to do just that. This device used for dimensional layout on raw gray and ductile iron castings has allowed us to check more dimensions at a higher accuracy giving ourselves and customers a comprehensive report of the product. The device's unique technology has eliminated the need to fixture each part before inspection; with little to no setup time along with the dependability, our customers receive reports faster.

3D Scanning Reports

The 3D Scanning Reports go above and beyond a standard dimensional report. Seneca Foundry also takes advantage of color mapping, reverse engineering, and the ability to inventory scan files, to constantly provide the highest possible quality from a cast iron manufacturer.

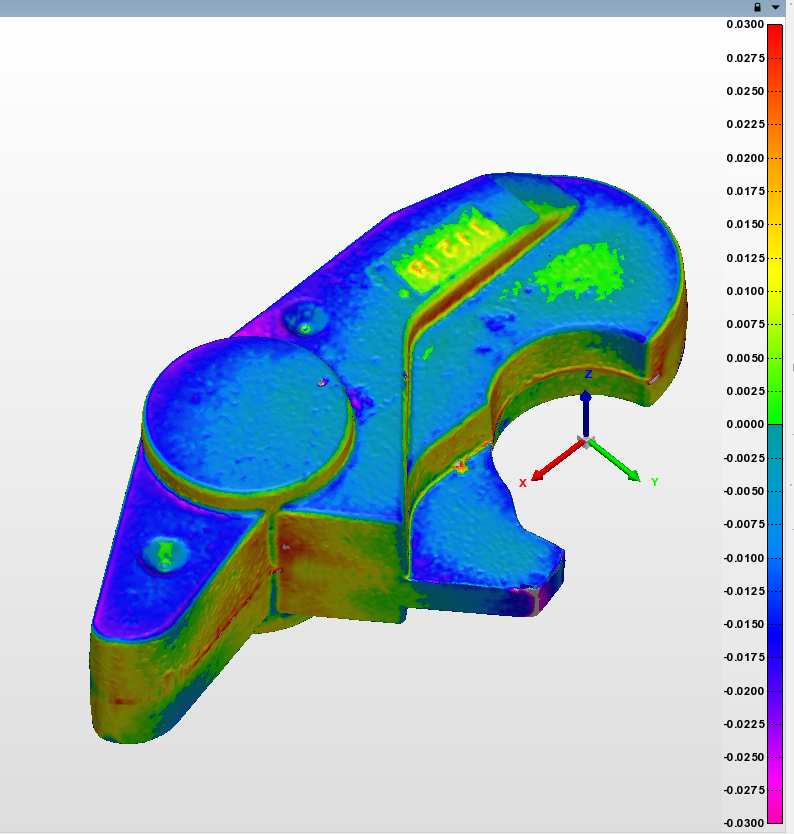

Color Mapping

Seneca Foundry's color mapping with a 3D scan compares surface deviations of our castings to a 3D model, pattern, and other castings like gray cast and ductile cast irons. The information given from a color map allows for better decision-making in a timely fashion.

Reverse Engineering

Reverse engineering with a 3D scan is a quick and cost-effective way to get a product out the door and back to the customer.

Inventory of scan files

An Inventory of Scan Files assists in total quality assurance over the life of production. During the initial sample, gray and ductile iron-casting scans are saved and can be used to identify any changes over time.

Are you interested in starting your next 3D Scanning project?

Contact us Today